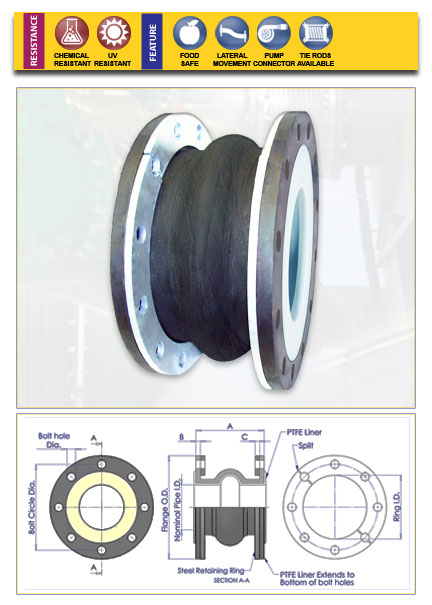

OVERVIEW: The Tefspool expansion joints are designed for industrial corrosive chemical applications, with an integral PTFE liner and EPDM rubber. It is used in many industrial applications, including those in pulp and paper, where the need to resist corrosive attack at higher pressures is paramount. Rated to 250F.

The strength of a rubber expansion joint with all PTFE wetted parts make the Tefspool an important expansion joint alternative.

Control units are optional.

See the Specification Assistant button below for specification wording details.

FEATURES:

- Integral PTFE chemical resistant liner in a robust rubber spool expansion joint

APPLICATIONS:

- Highly corrosive pressurized piping systems with moderate temperatures

TEMPERATURE: 250° F

swipe to see more products

|

DIA

(in)

|

PRES

(psi)

|

VAC

(in Hg)

|

LNGTH

(in)

|

COMPR

(in)

|

EXTEN

(in)

|

LATERAL

(in)

|

ROT

(deg)

|

WT

(lbs)

|

SPRING_RATE

(lbs/in)

|

EF AREA

(sq in)

|

|---|---|---|---|---|---|---|---|---|---|---|

| 1.5 | 225 | 30 | 6 | 1.25 | .625 | .625 | 28 | 4 | 400 | 1.8 |

| 2 | 225 | 30 | 6 | 1.25 | .625 | .625 | 25 | 6 | 425 | 3.1 |

| 2.5 | 225 | 30 | 6 | 1.25 | .625 | .625 | 20.2 | 7 | 450 | 4.9 |

| 3 | 225 | 30 | 6 | 1.25 | .625 | .625 | 18 | 8.5 | 574 | 7.1 |

| 4 | 225 | 30 | 6 | 1.25 | .625 | .625 | 14.2 | 12 | 480 | 12.6 |

| 5 | 225 | 30 | 6 | 1.25 | .625 | .625 | 13 | 13.5 | 475 | 19.6 |

| 6 | 225 | 30 | 6 | 1.25 | .625 | .625 | 12.2 | 16.5 | 457 | 28.3 |

| 8 | 210 | 30 | 6 | 1.25 | .625 | .625 | 12 | 25.5 | 714 | 50.3 |

| 10 | 210 | 30 | 8 | 2.0 | 1.0 | 1.0 | 11.9 | 36 | 1042 | 78.5 |

| 12 | 210 | 30 | 8 | 2.0 | 1.0 | 1.0 | 11.3 | 53.5 | 1583 | 113.1 |

| 14 | 150 | 30 | 8 | 2.0 | 1.0 | 1.0 | 11.5 | 65 | 1724 | 153.9 |

| 16 | 150 | 30 | 8 | 2.0 | 1.0 | 1.0 | 10.1 | 77.5 | 1947 | 201.1 |

| 18 | 150 | 30 | 8 | 2.0 | 1.0 | 1.0 | 8.9 | 83 | 2393 | 254.5 |

| 20 | 150 | 30 | 8 | 2.0 | 1.0 | 1.0 | 8.1 | 84 | 2605 | 314.2 |

| 24 | 110 | 28 | 10 | 3.0 | 1.5 | 1.5 | 9.0 | 108 | 2850 | 452.4 |